loading

ZBGX type peripheral drive scraper and suction machine

普利斯

| Availability: | |

|---|---|

1. Purpose

The ZBGX peripheral drive mud scraper and suction machine is suitable for large, medium and small diameter radial flow sedimentation tanks with central water inlet, peripheral water outlet and central mud discharge. It is mainly used for suction and discharge of mud in urban sewage treatment plants or sedimentation tanks.

2. Structure and working principle

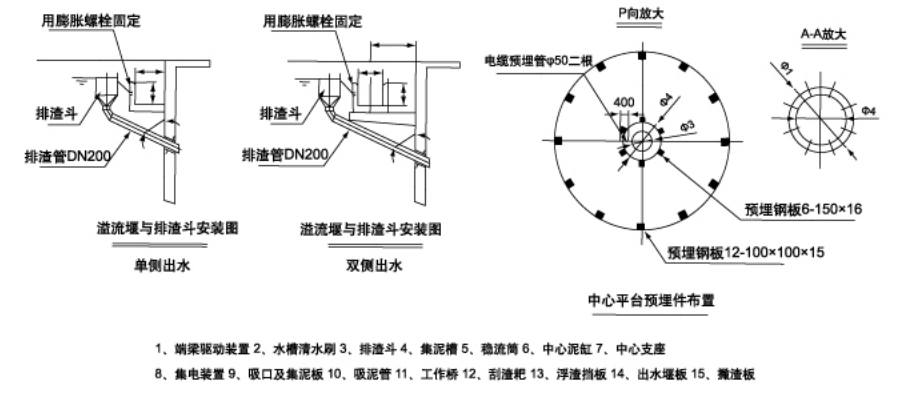

The equipment adopts peripheral drive. Sewage flows in from the inlet pipe in the center of the pool. After being diffused by the steady flow tube, it flows out evenly and radially to the periphery. The suspended sludge is deposited at the bottom of the pool after sedimentation . The driving device drives the working bridge to rotate along the periphery, and drives the sludge suction pipe system and sludge collection scraper to rotate. The scraper scrapes the sludge and then uses the sludge suction pipe to pump the sludge into the sludge collection tank based on the hydrostatic pressure in the pool and discharges it into the central mud tank, and then discharges it out of the pool through the central sludge discharge pipe. The scum on the water surface is introduced into the sludge discharge hopper through the rotating slag spreading device and discharged out of the pool; while the supernatant liquid overflows into the outlet tank through the triangular outlet weir plate and is discharged.

3. Main technical parameters and installation dimensions table

parameter | model | ZBGX-16 | ZBGX-20 | ZBGX-25 | ZBGX-30 | ZBGX-35 | ZBGX-40 | ZBGX-45 | ZBGX-50 | ZBGX-55 |

Pool diameterφ(m) | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |

Depth of surrounding pool H(m) | 3.5~4.5 (depending on user requirements) | |||||||||

Pool water depth Hz (m) | 3.0~4.0 (depending on user requirements) | |||||||||

Peripheral linear speed V(m/min) | 1.8~2.2 | |||||||||

Travel wheel size (mm | φ420×120 | φ420×150 | ||||||||

Motor power N(KW) | 0.37 | 0.55 | 0.75 | |||||||

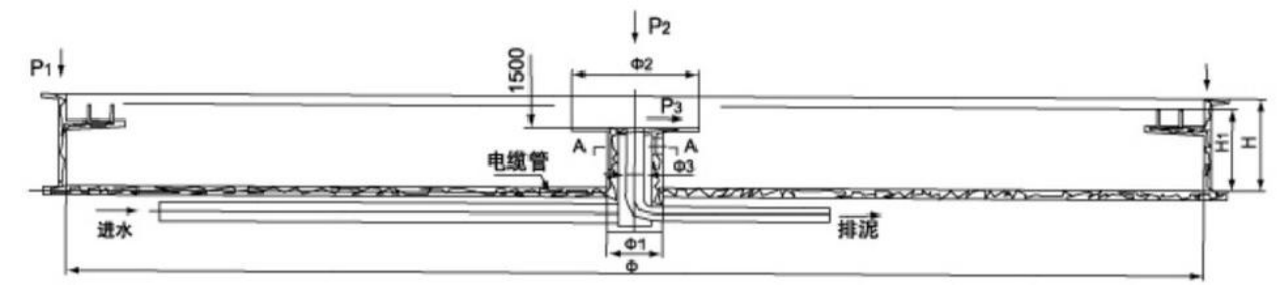

Installation dimensions (mm) | φ1 | 1100 | 1100 | 1200 | 1200 | 1500 | 1500 | 1800 | 1800 | 1800 |

φ2 | 2500 | 2500 | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 | |

φ3 | 2600 | 3000 | 3800 | 4500 | 4500 | 4500 | 5000 | 6000 | 6000 | |

φ4 | 2100 | 2300 | 3500 | 4000 | 4000 | 4000 | 4500 | 4500 | 4500 | |

H₂ | 500 | 500 | 600 | 760 | 760 | 760 | 760 | 760 | 760 | |

B | Rules are determined according to user requirements | |||||||||

Ha | According to user requirements | |||||||||

L | According to user requirements | |||||||||

Peripheral wheel pressure P₁(KN) | 9.0 | 11.5 | 15 | 19 | 22 | 25 | 28 | 30 | 32 | |

Center platform heavy direct load Pz (KN) | 17 | 23 | 30 | 37 | 82 | 100 | 112 | 122 | 175 | |

Center platform horizontal load P₃ (KN) | 9.5 | 13 | 17 | 22 | 28 | 28 | 30 | 32 | 40 | |

4. Work characteristics

The working bridge can be of half-bridge type or full-bridge type, and its materials can be carbon steel, stainless steel, aluminum alloy, etc.;

The driving device adopts a shaft-mounted helical gear reducer and a direct transmission of the driving roller, which has a compact structure and high mechanical efficiency;

The mud suction pipe adopts the form of a bell mouth, which has good mud suction effect; there are two ways of mud suction: self-priming and siphon type (the former is conventionally used);

5. Appearance and installation dimensions diagram

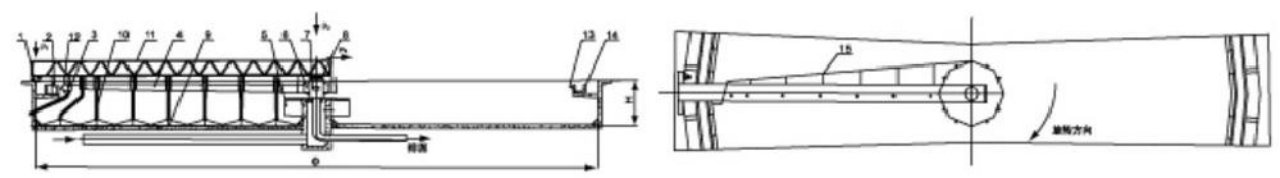

Half-bridge (single-side drive)

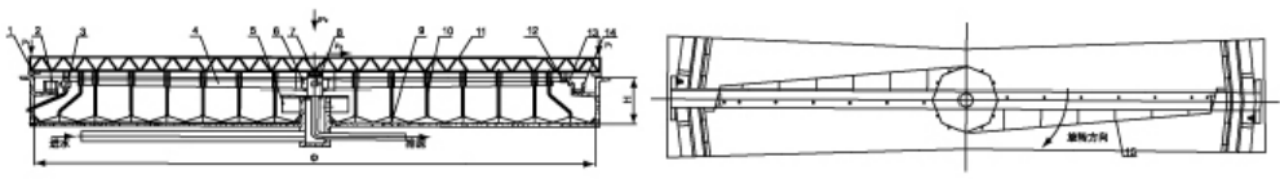

Full bridge (double-sided drive)

Civil engineering drawings

content is empty!