loading

OA2 type rotating drum spiral grid decontamination machine

普利斯

| Availability: | |

|---|---|

1. Purpose

The OA2 type rotary drum spiral grate decontamination machine is a new type of equipment independently researched, developed and manufactured by our company by absorbing foreign technology and combining it with the specific actual conditions of China's water treatment projects. It is suitable for fine grates in urban sewage treatment plants. It is also a new product that integrates the three functions of trapping, collecting, transporting and squeezing the grates.

2. Structure and working principle

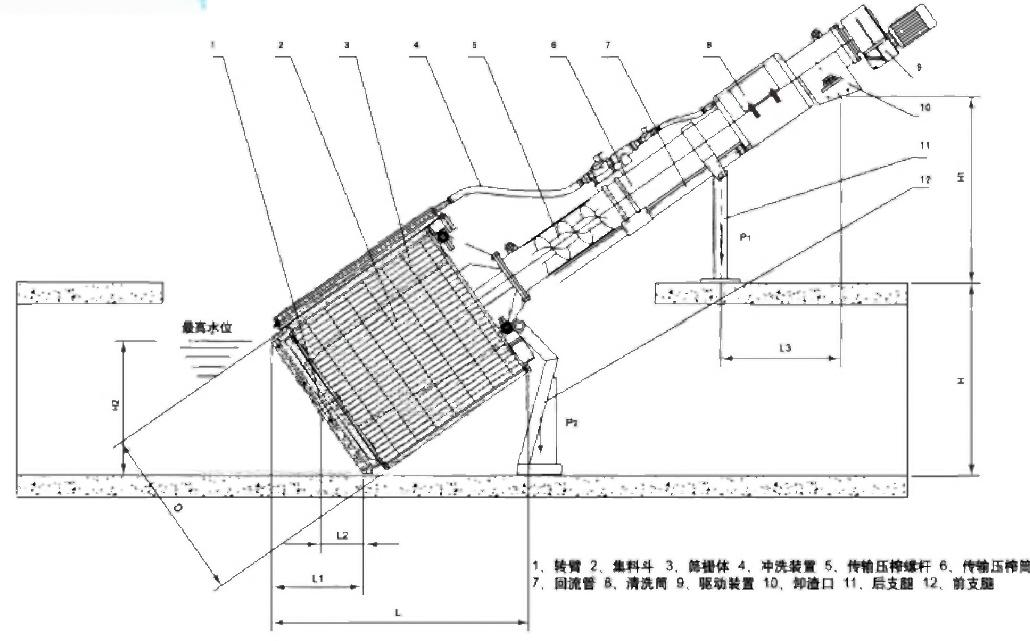

The equipment adopts a rotating drum spiral type, with a circular screen cylinder as the grid surface, and is installed in the water channel at an angle of 35° to the horizontal plane. When the sewage flows into the screen cylinder from the end of the grid, the filter residue larger than the screen gap is intercepted and deposited on the inner surface of the screen cylinder. The entire screen cylinder is powered by electricity. The machine drives the rotation, and the cleaning brush and flushing mechanism above the screen drum clean the screen surface, and the filter residue falls into the central material trough, which is lifted by the conveying screw. After being squeezed and dehydrated, it falls from the discharge port into the material box or conveyor for external transportation.

3. Main technical parameters and installation dimensions table

parameter | model | OAa-600 | OA₂-800 | OA-1000 | OA₂-1200 | OA-1400 | OA₂-1600 | OA₂-1800 | OA₂-2000 | OAz-2200 | OA2-2400 | OA-2600 |

Equipment width B(mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 180 | 2000 | 2200 | 2400 | 2600 | |

Track width B, (mm) | 620 | 820 | 1020 | 1220 | 1440 | 1640 | 1840 | 2040 | 2240 | 2440 | 2640 | |

Grid gap b (mm) | 1-5 | |||||||||||

Installation angle a(°) | 35 | |||||||||||

Depth of channel H(mm) | H₂+300~500 | |||||||||||

Height from material opening to platform H₁ (mm) | 1000~1500 | |||||||||||

Rotation speed n(r/min) | *6 | |||||||||||

Motor power N(kw) | 1.1 | 1.5 | 2.2 | |||||||||

Installation dimensions (mm) | L | 860 | 1100 | 1340 | 1580 | 1810 | 2040 | 2280 | 2670 | 2700 | 3080 | 3410 |

L₁ | 330 | 450 | 560 | 680 | 780 | 910 | 1000 | 1120 | 1230 | 1350 | 1460 | |

L | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |

L₃ | 1230 | 1420 | 1420 | 1310 | 1590 | 1590 | 1590 | 1520 | 1520 | 1520 | 1520 | |

400 | 520 | 670 | 800 | 930 | 1110 | 1230 | 1300 | 1500 | 1680 | 1750 | ||

Civil load | P₁ (KN) | 6.6 | 7.7 | 9.8 | 11.0 | 18.7 | 21.0 | 23.4 | 26.1 | 36.6 | 40.4 | 45.0 |

P₂ (KN) | 3.3 | 3.86 | 4.9 | 5.5 | 9.4 | 10.5 | 11.7 | 13.1 | 18.3 | 20.2 | 22.3 | |

4. Main features

■The whole machine has a compact structure, small footprint, and is easy to install, operate and maintain;

■The equipment grid gap is small and can generally be designed within the range of 1 to 5 mm;

■High sewage interception efficiency. Closed conveying. No pollution to the environment:

■The equipment can implement fully automatic control, with stable operation, low energy consumption and low noise;

■The equipment is automatically cleaned during operation to avoid clogging.

5. Water flow meter

model parameter | OA-600 | OAa-800 | OA-1000 | OAa-1200 | OAx-1400 | OAx-1600 | OA-1800 | OA-2000 | OAa-2200 | OAx-2400 | OAa-2600 | ||

Water depth in front of gate Ho (mm) | 400 | 520 | 670 | 800 | 930 | 1110 | 1230 | 1300 | 1500 | 1680 | 1750 | ||

Gate flow velocity v(m/s) | 0.8 | ||||||||||||

question title (mm |

Cross the water

(L/s) | 36 | 60 | 100 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | |

2 | 54 | 90 | 154 | 214 | 306 | 402 | 510 |

一 | |||||

3 | 65 | 110 | 192 | 262 | 373 | 490 | 622 | 768 | 928 | 1104 | 1516 | ||

4 | 68 | 120 | 203 | 280 | 402 | 572 | 756 | 930 | 1122 | 1300 | 1710 | ||

5 | 70 | 130 | 224 | 310 | 400 | 616 | 815 | 1020 | 1213 | 1456 | 1840 | ||

6. Appearance and installation dimensions diagram

content is empty!