1. Product Overview

The S series self-cleaning filter is an electric brush-cleaning water filter. The motor drives a set of stainless steel rigid elements installed inside the filter screen.

The fully automatic self-cleaning filter suitable for harsh environments can be equipped with a 3500 micron-300 micron filter for different use requirements. The self-cleaning process of the filter is started by a pressure difference signal and time.

Structural type: vertical, horizontal, online.

2. Cleaning process

When the pressure difference between the filter inlet and outlet reaches the preset value of 0.5bar or the time setting value, the filter will start a self-cleaning process. The entire self-cleaning process consists of two steps: opening the diaphragm drain valve located on the upper end cover of the filter; the motor drives the stainless steel brush in the filter screen to rotate, and the impurities captured by the filter screen are brushed down by the steel brush and discharged from the drain valve. The entire cleaning process takes about 15-30 seconds. The system does not flow during cleaning. The entire operation process of the filter is controlled by a control box equipped with it.

3. Cleaning steps

1. When the pressure difference switch detects that the pressure difference inside and outside the filter reaches the preset value (0.5bar).

2. The diaphragm drain valve is opened to communicate with the atmosphere.

3. The motor drives the steel brush in the filter to rotate.

4. The diaphragm drain valve is closed.

4. Control system

It adopts industrial single-chip PLC automatic control and displays in full Chinese. Backwashing can be controlled based on pressure difference or timing, and can be cleaned manually or forcefully, even when the power is off. Set filter interval and cleaning time on site. Operation signal, cleaning signal, fault signal output and communication signal output.

5. Manufacturing materials

Filter housing: carbon steel sprayed with epoxy resin (stainless steel available upon request)

Filter: stainless steel

Cleaning device: stainless steel

Drain valve: cast iron

Seal: synthetic rubber, polytetrafluoroethylene

6. Standard filter level:

Micron | 3500 | 2500 | 1500 | 800 | 500 | 300 | 200 | 130 | 100 |

mm | 3.5 | 2.5 | 1.5 | 0.8 | 0.8 | 0.3 | 0.2 | 0.13 | 0.1 |

目 | 4 | 6 | 10 | 20 | 30 | 50 | 75 | 120 | 155 |

7. Application scope

1. Cooling water treatment - cooling tower, supplementary water system, air conditioning system, DC system water filtration to reduce the generation of sediments in the heat exchanger and maintain its cooling effect. 2. Raw water treatment - can filter surface river water, lake water, sea water, reservoir water, well water and groundwater to remove sand, bacteria, algae, organic matter, etc.

3. Industrial circulating water filtration - used in equipment that has certain requirements on water quality, such as: cooling towers, rolling mills, continuous casters, polishing, water pumps, solenoid valves, ion exchangers, sprayers, heat exchangers, etc. or on water supply and drainage pipelines. It can filter out impurities in the water and avoid clogging of pipelines, nozzles and other parts.

4. Irrigation - especially suitable for water sources with high flow and high impurity content, agricultural irrigation, sprinkler irrigation, parks, golf courses, turf irrigation, etc.

5. Paper industry - white water filtration.

8. Technical performance

●Single unit flow rate: 150-2800m³/h, larger flow rate can be connected by multiple units in parallel

●Minimum working pressure: 0.2MPa Working pressure: 1.0-1.6MPa

●Operating temperature: 75 degrees Celsius

●Filtration precision: 300-3500 microns

●Control mode: pressure difference, time and manual

●Cleaning time: 20-60 seconds. Cleaning mechanism speed: 14-20rpm

●Cleaning pressure loss: 0.01-0.8MPa

●Control voltage: AC 220V

●Working voltage: three-phase 380V, 50HZ

●LCD display interface, user-friendly design and easy operation

9. Technical parameters and dimensions

model | ST-150 | ST-200 | ST-250 | ST-300 | ST-350 | ST-400 | ST-450 | ST-500 | ST-600 |

Pipe diameter(mm) | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Filter flow (m³/h) | 150 | 300 | 450 | 600 | 900 | 1200 | 1500 | 2000 | 2800 |

Filter area (cm²) | 7500 | 7500 | 7500 | 14500 | 17500 | 21500 | 25000 | 25000 | 2600 |

Drain valve DN (mm) | 50 | 50 | 50 | 50 | 80 | 80 | 80 | 80 | 80 |

Amount of water for one cleaning (L) | 150 | 150 | 200 | 200 | 350 | 350 | 350 | 350 | 350 |

Motor power(KW) | 0.55 | 0.55 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

Weight(Kg) | 310 | 320 | 350 | 460 | 510 | 638 | 956 | 1056 | 1243 |

model | D(mm) | H(mm) | H1(mm) | H2(mm) | H2*(mm) | L1(mm) | L2(mm) | L(mm) |

St-150 | 430 | 550 | 1100 | 1360 | 2000 | 400 | 360 | 800 |

St-200 | 430 | 550 | 1100 | 1360 | 2000 | 400 | 360 | 800 |

St-250 | 430 | 550 | 1100 | 1360 | 2000 | 400 | 360 | 800 |

ST-300 | 630 | 685 | 1360 | 1660 | 2600 | 510 | 460 | 860 |

ST-350 | 630 | 685 | 1360 | 1660 | 2600 | 510 | 460 | 860 |

ST-400 | 724 | 900 | 1380 | 1710 | 2800 | 610 | 510 | 1100 |

ST-450 | 824 | 765 | 1500 | 1850 | 2850 | 630 | 600 | 1300 |

ST-500 | 924 | 920 | 1720 | 2100 | 3000 | 650 | 660 | 1400 |

ST-600 | 1024 | 1010 | 1850 | 2300 | 3300 | 700 | 710 | 1600 |

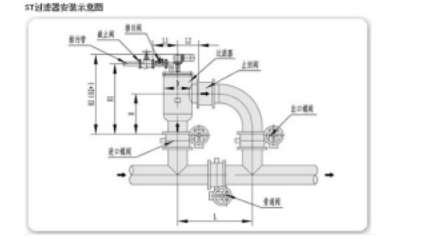

10. ST filter installation diagram

content is empty!