loading

ZBG type peripheral transmission mud scraper

普利斯

| Availability: | |

|---|---|

1. Purpose

The ZBG peripheral transmission mud scraper is suitable for medium and large diameter radial flow sedimentation tanks with central water inlet, peripheral water outlet and central mud discharge. It is mainly used for mud discharge in the primary sedimentation tank of urban sewage treatment plants. This equipment obtained the Science and Technology Achievements Promotion Project Certificate of the Ministry of Construction in 2002.

2. Structure and working principle

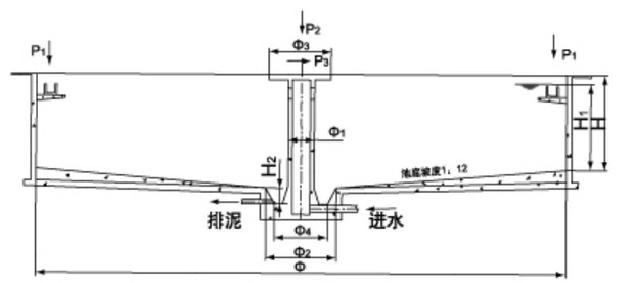

The equipment adopts peripheral transmission. The sewage flows in from the water inlet pipe in the center of the pool. After being diffused by the steady flow tube, it flows out evenly and radially to the periphery. The suspended sludge is deposited at the bottom of the pool after sedimentation. The driving device drives the working bridge to rotate along the periphery and drives the scraper arm and scraper plate to rotate. After the sludge is scraped from the periphery of the pool to the central sludge collecting tank, it is discharged from the pool through the sludge discharge pipe by the hydrostatic pressure in the pool. The scum on the water surface is skimmed to the edge of the pool through the skimming device, and then scraped into the slag discharge hopper by the scraper rake and discharged out of the pool; while the supernatant liquid overflows into the outlet tank through the triangular outlet weir plate and is discharged.

3. Main technical parameters and installation dimensions table

parameter | model | ZBG-16 | ZBG-20 | ZBG-25 | ZBG-30 | ZBG-35 | ZBG-40 | ZBG-45 | ZBG-50 | ZBG-55 |

Pool diameter (m) | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |

Depth of surrounding pool H(m) | 3.5~4.5 (depending on user requirements) | |||||||||

Pool water depth Hz (m) | 3.0~4.0 (depending on user requirements) | |||||||||

Peripheral linear speed V(m/min) | 2.0~3.0 | |||||||||

Travel wheel size (mm) | 400×120 | 420×150 | ||||||||

Motor power N(KW) | 1.1 | 1.5 | 2.2 | 3.0 | 4 | |||||

Installation dimensions (mm) | φ1 | 1100 | 1100 | 1200 | 1200 | 1500 | 1500 | 1800 | 1800 | 1800 |

φ2 | 2500 | 2500 | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 | |

φ3 | 2600 | 3000 | 3800 | 4500 | 4500 | 4500 | 5000 | 6000 | 6000 | |

φ4 | 2100 | 2300 | 3500 | 4000 | 4000 | 4000 | 4500 | 4500 | 4500 | |

H2 | 500 | 500 | 600 | 760 | 760 | 760 | 760 | 760 | 760 | |

B | According to user requirements | |||||||||

H3 | According to user requirements | |||||||||

According to user requirements | ||||||||||

Peripheral wheel pressure P₁(KN) | 9.0 | 11.5 | 15 | 19 | 22 | 25 | 28 | 30 | 32 | |

Center platform vertical load P₂ (KN) | 17 | 23 | 30 | 37 | 82 | 100 | 112 | 122 | 175 | |

Center level horizontal load P(KN) | 9.5 | 13 | 17 | 22 | 28 | 28 | 30 | 32 | 40 | |

4. Work characteristics

1. The working bridge can be half-bridge or full-bridge, and its material can be carbon steel, stainless steel or aluminum alloy;

2. The driving device adopts a shaft-mounted helical gear reducer and a direct transmission of the driving roller, which has a compact structure and high mechanical efficiency;

3. The scraper collects mud in a logarithmic spiral trajectory, with good continuity and high mud collection efficiency; when the slope of the bottom of the pool is 1:10, the resistance when scraping mud can be reduced;

5. Appearance and installation dimensions diagram

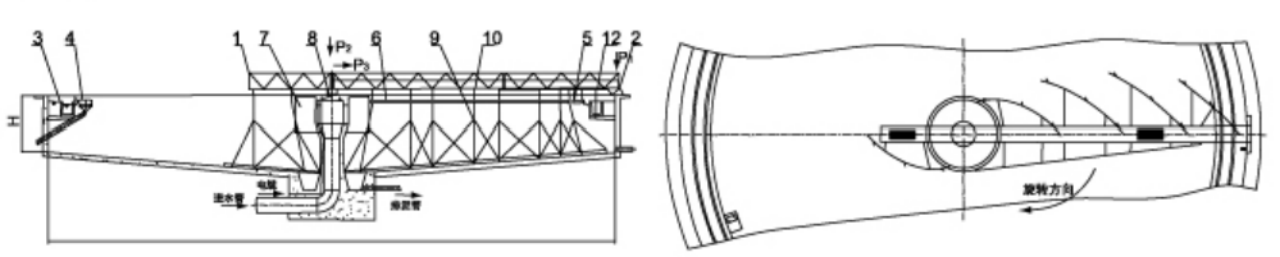

half bridge

full bridge

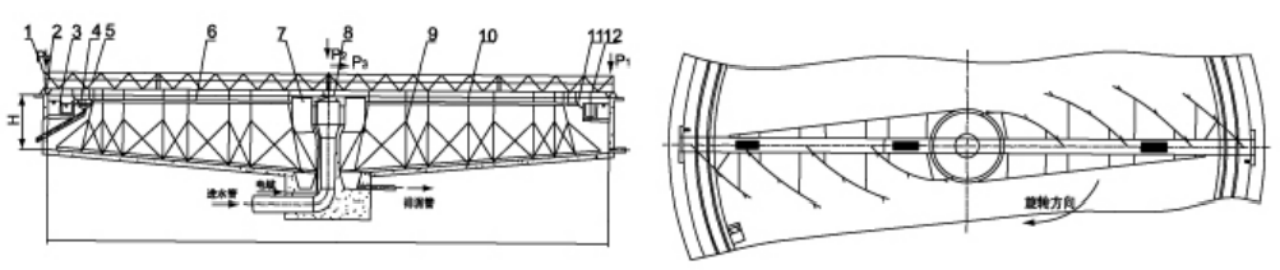

Civil engineering drawings

content is empty!