loading

HTJY type fully automatic dosing device

普利斯

| Availability: | |

|---|---|

1. Main uses

The HTJY fully automatic dosing device is widely used as an auxiliary equipment for municipal water treatment and waterproof sludge treatment. It can continuously and efficiently complete polymer compounding and mixing to obtain a homogeneous active polymer solution.

2. Structure and working principle

The equipment uses a jet mixer, which uses high-speed hydraulic power to disperse the agent or powder to increase fineness, increase the contact between the agent or powder and water, the penetration area, and shorten the dissolution time. The equipment uses a three-tank overflow combination, namely preparation, aging and dosing. It uses gravity and solubility to generate the specific gravity difference of the solution, automatically separates the dissolved and undissolved, and then stirs with a low-speed stirrer to improve the uniformity of the solution.

3. Main technical parameters and installation dimensions table

parameter | model | HTJY-500 | HTJY-1000 | HTJY-1500 | HTJY-2000 | HTJY-3000 | HTJY-4000 |

Preparation capacitya(L/h) | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | |

Overall dimensions (B×L×H) | 900*1500*1650 | 1000*1625*1750 | 1000*2440*1800 | 1220*2440*1800 | 1220*3200*2000 | 1450*3200*2000 | |

Dry powder dosing motor power N (KW) | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | |

mixer | Blade diameter (mm) | 250 | 250 | 250 | 250 | 250 | 250 |

Vertical shaft speed n(r/min) | 96 | 96 | 96 | 96 | 96 | 96 | |

PowerN(KW) | 0.75×2 | 0.75×2 | 0.75×2 | 0.75×2 | 0.75×2 | 0.75×2 | |

Dosing screw pump | Flow (m3/h) | 1.0 | 1.0 | 1.5-2.0 | 1.5-2.0 | 3.0-5.0 | 3.0-5.0 |

Lift(m) | 20 | 20 | 20 | 20 | 20 | 20 | |

Power N3(KW) | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | |

Water inlet diameter DN1 (mm) | 20 | 20 | 25 | 25 | 32 | 32 | |

Outlet pipe diameter DN2 (mm) | 20 | 20 | 25 | 25 | 32 | 32 | |

Installation dimensions (mm) | B | 900 | 1000 | 1000 | 1220 | 1450 | |

| L | 1500 | 1625 | 2440 | 2440 | 3200 | 3200 | |

H | 1650 | 1750 | 1800 | 1800 | 2000 | 2000 | |

H1 | 800 | 8 | 1050 | 1050 | 1350 | 1350 | |

4. Work characteristics

■Three-tank integrated continuous preparation, easy operation and maintenance;

Dry powder or liquid polymer can be double fed to meet different needs;

■PLC fully automatic operation, saving labor;

■Screw pump or metering pump can be used to add chemicals (the former is conventionally used), and the metering is adjustable;

■The equipment has no base or fixation, has a beautiful appearance and is easy to maintain. Low fees.

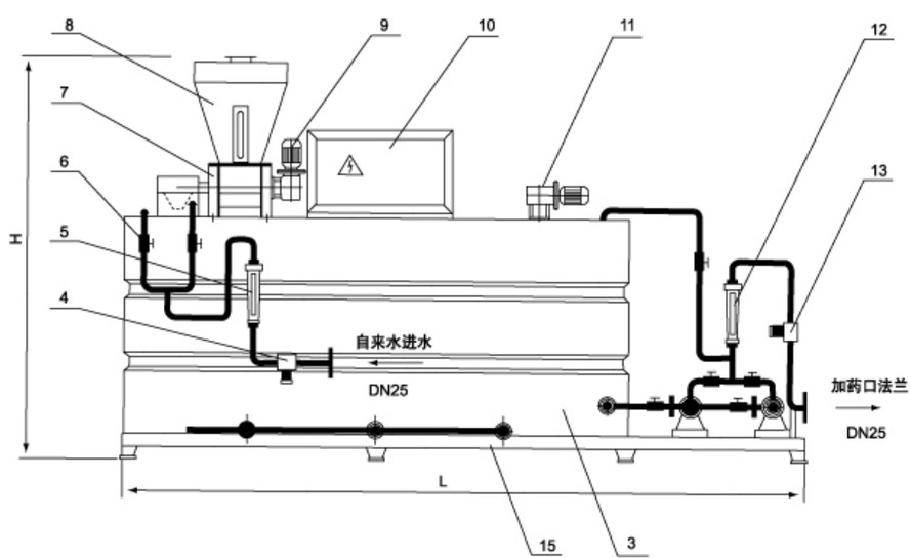

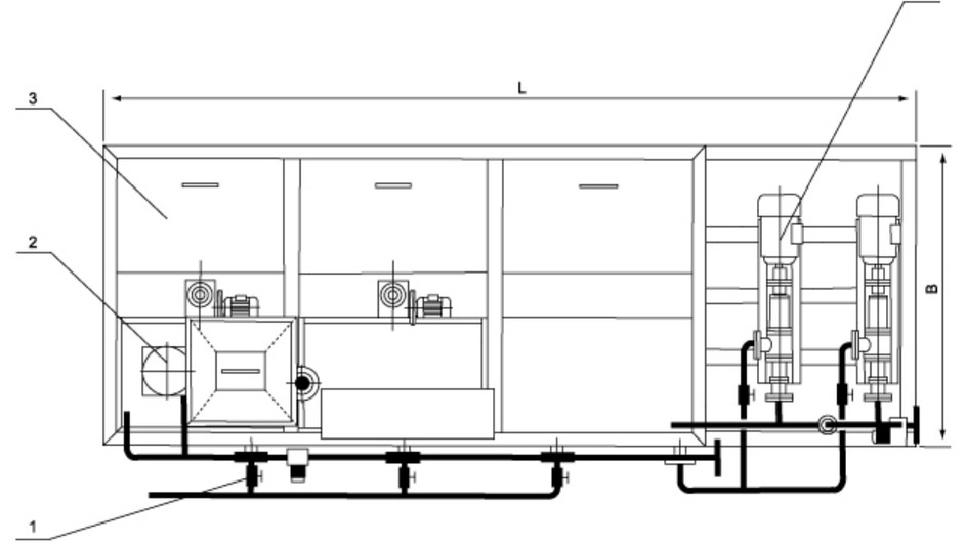

5. Appearance and installation dimensions diagram

1. Vent valve 2. Venturi 3. Medicine box 4. Water inlet solenoid valve 5. Water inlet flow meter 6. Water inlet valve 7. Dry powder dosing 8. Chemicals

9. Dry powder dosing motor 10, electric control box 11, stirring motor 12, liquid flow meter 13, dosing solenoid valve 14, dosing screw pump 15. Rack

content is empty!