loading

Semi-immersed filter cloth turntable filter

普利斯

| Availability: | |

|---|---|

1. Product Overview

The filter cloth turntable filter (microfiltration cloth filter) is one of the most popular filters in the world. Currently, 700 sewage plants across the country have adopted this technology. The filter cloth turntable filter has good processing effect, high water quality, stable equipment operation, and has the currently recognized reclaimed water reuse certificate-Title22 certificate.

2. Product use

The filter cloth rotating disk filter is mainly used for cooling circulating water treatment and wastewater reuse after advanced treatment. As cooling water and circulating water, filter and reuse: inlet water quality SS≤80mg/L or less, outlet water quality SS≤20mg/L. It is used for the advanced treatment of sewage. It is installed after the conventional activated sludge method, delayed aeration method, SBR system, oxidation ditch system, trickling filter system, and oxidation pond system. It can be used in the following fields: ①Remove total suspended solids ②Add chemicals to remove phosphorus ③Remove heavy metals, etc. The filter cloth turntable filter is used to filter the effluent from the activated sludge final sedimentation tank. The designed water quality is: inlet water SS: 30mg/L (can withstand 80-100mg/L), effluent SSs5mg/L, turbidity ≤ 2 NTU. In actual operation, the effluent is of higher quality, and the effluent turbidity is generally around 1.

3. Working principle

The operating status of the filter cloth turntable filter is divided into two relatively independent and simultaneous processes: raw water filtration and backwashing and mud discharge. Both are done in different locations on the same filter. a. Raw water filtration: The sewage to be filtered enters the inside of the rotating central cylinder of the filter through the gravity drop. The rotating central cylinder is provided with a square water distribution hole. The sewage flows into the rotating drum through the water distribution port, enters the inner tank of each filter plate of the filter, and then passes through the filter cloth, so that the suspended solids in the sewage are trapped on the inside of the filter plate, and the filtered water is discharged through the overflow water collection. The device is at rest while filtering.

b. Backwashing: The sludge in the sewage is collected on the inside of the filter cloth, gradually forming a sludge layer. As sludge accumulates on the filter cloth, the filtration resistance of the filter cloth increases, and the water level in the filter gradually rises. Monitor changes in the liquid level in the pool through a liquid level gauge. When the liquid level in the pool reaches the cleaning (high water level), The PLC controls the start of the backwash process: the filter plate rotates in the central cylinder, driving the reducer to rotate at a speed of 1 to 3 rpm. At the same time, the backwash water pump starts. The backwash water pump extracts filtered water and then flushes the filter cloth at the top position from the outside to the inside through the high-pressure umbrella-shaped injection system located on the top of the filter disc, thereby removing the dirt accumulated on the inner surface of the filter cloth, and then discharges it through the sewage pipe. Clean the nozzle and move it up and down to clean the filter cloth completely without any dead ends, saving cleaning water consumption. The number and duration of backwashing are adjustable. During backwashing, the filter tank can continuously filter.

4. Main features

■Continuous operation: 24 hours of continuous operation without backwashing. It can be continuously filtered while backwashing.

■Good processing effect. The pore size of the filter cloth is 10 microns, which can intercept tiny particles with a particle size less than 10 microns (μm), thus ensuring the quality and stability of the effluent.

■Backwash water consumption is low. The water consumption of backwashing is 1%~2% of the total incoming water, which is far less than the amount of water required for filtration by other filtration equipment.

■Small head loss. Generally 0.05~0.25m.

■Low running costs. (Excluding the cost of adding phosphorus removal chemicals) the operating cost is less than 0.01 yuan/ton of water.

■Low installed power.

■Operation fully automated control. Filtration, backwashing, etc. are all controlled by programs and equipped with multiple protections. Daily operation and management are not required.

■Small footprint. The rotating disk filter plate is designed vertically, so that it has a large filtration area in a small footprint.

■Short design and construction cycle. The rotary disk filter is modular as a whole, making the design and construction convenient and fast, and it is easy to expand.

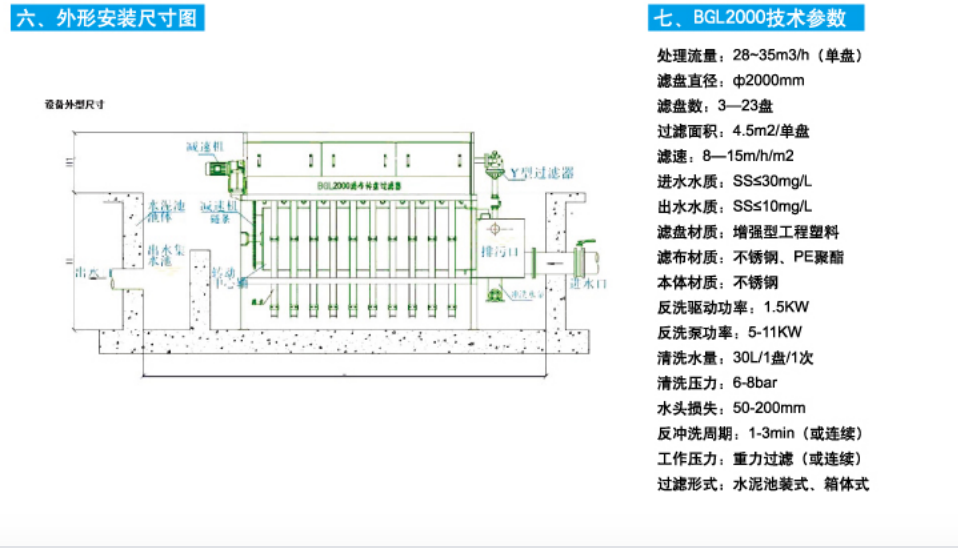

5. Main technical parameters and installation dimensions table

model | Cement pool type turntable filter strong type I | Stainless steel box type filter type II | |||||

L(mm) | W(mm) | H(mm) | H1(mm) | L(mm) | W(mm) | H(mm) | |

BGL 2000-3 | 3875 | 2250 | 2100 | 785 | 2435 | 2290 | 2470 |

BGL2000-4 | 4100 | 2250 | 2100 | 785 | 2670 | 2290 | 2470 |

BGL2000-5 | 4336 | 2250 | 2100 | 785 | 2905 | 2290 | 2470 |

BGL2000-6 | 4572 | 2250 | 2100 | 785 | 3140 | 2290 | 2470 |

BGL2000-7 | 4808 | 2250 | 2100 | 785 | 3375 | 2290 | 2470 |

BGL2000-8 | 5044 | 2250 | 2100 | 785 | 3610 | 2290 | 2470 |

BGL2000-9 | 5280 | 2250 | 2100 | 785 | 3845 | 2290 | 2470 |

BGL2000-10 | 5516 | 2250 | 2100 | 785 | 4080 | 2290 | 2470 |

BGL2000-11 | 5752 | 2250 | 2100 | 785 | 4315 | 229 | 2470 |

BGL2000-12 | 4450 | 2250 | 2100 | 785 | 4550 | 2290 | 2470 |

BGL2000-13 | 6224 | 2250 | 2100 | 785 | 4785 | 2290 | 2470 |

BGL2000-14 | 6460 | 2250 | 2100 | 785 | 5020 | 2290 | 2470 |

BGL2000-15 | 6696 | 2250 | 2100 | 785 | 5255 | 2290 | 2470 |

BGL2000-16 | 6932 | 2250 | 2100 | 785 | 5490 | 2290 | 2470 |

BGL2000-17 | 7168 | 2250 | 2100 | 785 | 5725 | 2290 | 2470 |

BGL2000-18 | 7404 | 2250 | 2100 | 785 | 5960 | 2290 | 2470 |

BGL2000-19 | 7640 | 2250 | 2100 | 785 | 6195 | 2290 | 2470 |

BGL2000-20 | 7876 | 2250 | 2100 | 785 | 6430 | 2290 | 2470 |

BGL2000-21 | 8112 | 2250 | 2100 | 785 | 6665 | 2290 | 2470 |

BGL2000-22 | 8348 | 2250 | 2100 | 785 | 6900 | 2290 | 2470 |

BGL2000-23 | 8584 | 2250 | 2100 | 785 | 7135 | 2290 | 2470 |

content is empty!