1. Product introduction

The company introduced Japanese technology and combined with the characteristics of Chinese sludge to launch a new generation of sludge dehydration equipment without filter cloth (belt), no fouling, anti-wear, and low energy consumption - the disc spiral sludge dehydrator. It got rid of the technical problems of previous generations of sludge dehydration equipment that occupied a large area, were unable to handle low-concentration sludge, and were difficult to handle special sludge containing oil.

The main body of the stacked screw sludge dehydrator is a solid-liquid separation device composed of a fixed ring and a moving ring that swim with each other and a penetrating spiral shaft. The solid-liquid separation area is divided into two parts: a concentration section and a dehydration section. The sludge is pushed through the spiral shaft and is compressed and dehydrated. The water seeps out from the annular gap between the moving fixed ring and the moving ring. What is unique about this machine is that the movement of the moving ring against the fixed ring is driven by a special drive device for the spiral shaft, which prevents friction and wear of the filter components and greatly extends the service life of the entire machine.

2. Product structure

The core part of the disc spiral sludge dehydrator is one or several sets of filter units composed of a spiral push shaft, multiple fixed stacks and multiple moving stacks. Each set of filter units is divided into two parts: a concentration section and a dehydration section. From the sewage inlet of the concentration section to the mud cake outlet of the dehydration section, the pitch of the spiral shaft gradually becomes smaller, and the gap between the fixed ring and the moving ring also gradually becomes smaller. A back pressure plate is provided at the sludge outlet to adjust the pressure in the spiral chamber. The stacked screw sludge dewatering machine completes the concentration and dehydration of sludge in one cylinder, replacing the traditional filter cloth and centrifugal filtration methods with a unique and subtle filter model.

3. Working principle

Concentration: When the spiral push shaft rotates, the multiple solid and active laminations located on the periphery of the push shaft move relative to each other. Under the action of gravity, water is filtered out from the gaps between the relatively moving laminations, achieving rapid concentration.

Dehydration: The concentrated sludge continues to move forward as the spiral shaft rotates; along the direction of the mud cake outlet, the pitch of the spiral shaft gradually becomes smaller, the gap between the rings gradually becomes smaller, and the volume of the spiral cavity continues to shrink; under the action of the back pressure plate at the outlet, the internal pressure gradually increases, and driven by the continuous operation of the spiral push shaft, the water in the sludge is squeezed out, and the solid content of the filter cake continues to increase, ultimately achieving continuous dehydration of the sludge.

Self-cleaning: The rotation of the spiral shaft drives the moving ring to continuously rotate. The equipment relies on the movement between the fixed ring and the moving ring to achieve a continuous self-cleaning process, thus cleverly avoiding the common clogging problem of traditional dehydrators.

4. Work advantages

Reduce the sludge treatment area: it can directly process the sludge in the aeration tank or the sludge in the secondary sedimentation tank. There is no need to set up a sludge concentration tank and storage tank, saving space.

Improve the phosphorus removal function of the system: The sludge is dehydrated under aerobic conditions, avoiding the release of sludge phosphorus under anoxic or anaerobic conditions, and improving the dephosphorization function of the system.

Simple operation and management: There are no filter cloths, filter holes and other easy-to-clog components, and the operation is safe and simple. Combined with the fully automatic dosing system, it can achieve 24-hour unattended operation.

Reduce system processing load: integrated sewage and sludge treatment to reduce the burden of subsequent biochemical reactors

5. Product advantages

The applicable sludge concentration range is wide, up to 2000mg/L-50000mg/L.

It has strong resistance to oily sludge, is easy to separate and does not block.

Clean and environmentally friendly, no odor, no noise, no need for high-pressure washing, and no secondary pollution.

Small and compact, it saves water and energy. The unit power consumption is only 0.1kwh/kgDS, and the unit water consumption is only 0.03th.

Routine maintenance is simple and can be operated continuously without the need for dedicated personnel or oil changes.

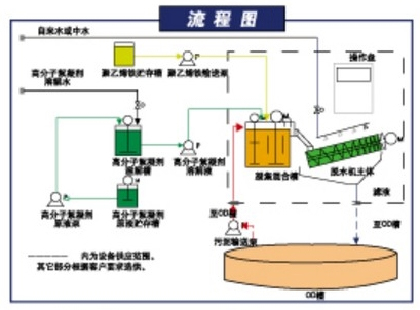

6. Process flow chart

7. Analysis of various dehydration operations

project | Disc spiral dehydrator | Belt pressure source machine | Decanter centrifuge | Van type pressure source machine |

Dehydration method | Moving piece spiral dehydration | Gravity and squeeze dehydration | Centrifugal dehydration | Pressurized dehydration |

Electricity consumption | very small | Larger | very big | 中 |

water consumption | very small | difficult | 小 | 中 |

operating noise | very small | 中 | difficult | 小 |

Maintenance difficulty | easy | 难 | difficult | easy |

Sludge viscosity requirements | 中 | 中 | ||

Mud cake moisture content | About 75-80% | >80% | about 80% | <80% |

degree of automation | 高 | 高 | 高 | 低 |

workplace | clean | 差 | 中 | worst |

DL disc spiral dehydrator selection parameters

model | Theoretical throughput | Fixed number of moving pieces | Host power | Flocculation motor power | Remark |

DL311 | 3-5t/m³/h | 612 | 1.50 | 0.75 | Single connection |

DL312 | 6-10t/m³/h | 1224 | 1.50×2 | 0.75 | dual connection |

DL313 | 9-15t/m²/h | 1826 | 1.50×3 | 1.1×2 | triple link |

DL314 | 12-20t/m³/h | 2448 | 1.50×4 | 0.75×2 | Quad link |

DL411 | 6-10t/m²/h | 758 | 2.20 | 1.10 | Single connection |

DL412 | 12-20t/m³/h | 1516 | 2.20×2 | 1.10 | dual connection |

DL413 | 18-30t/m³/h | 2274 | 2.20×3 | 1.50 | triple link |

DL414 | 24-35t/m³/h | 3032 | 2.20×4 | 1.50×2 | Quad link |

content is empty!