Denitrification deep bed filter is a kind of deep treatment filtration process in sewage treatment. It originated in the United States in the 1970s. This treatment process has centralized functions and flexible operation. It can simultaneously perform the functions of physical filtration to intercept SS (suspended solids), chemical microflocculation to remove TP (total phosphorus), and biological denitrification to remove TN (total nitrogen).

The denitrification filter uses quartz sand of special specifications and shapes as the film medium for denitrifying organisms. At the same time, the deep bed is an excellent structure for removing nitrate nitrogen (NO3-N) and suspended solids. The specific surface area of 2 to 4 mm medium is larger. A filter bed with a depth of 1.8-2.5m is enough to avoid channeling or penetration. Even if sludge expansion or abnormality occurs in the front-end treatment process, it can reduce the occurrence of hydraulic penetration of the filter bed. The medium has a good suspended solids interception effect. During the backwash cycle, each square meter of filter area can ensure the retention of ≥7.3kg solid suspended solids. The high solids load greatly extends the filtration cycle of the filter, reduces the number of backwashes, and can easily cope with abnormal situations such as peak flow or sludge expansion in treatment plants. The continuous interception of suspended solids will increase the head loss, so backwashing is required to remove the trapped solids. Due to the high solids load and deep bed, higher intensity backwashing is required. The filter uses air and water to backwash together. The backwash sewage is generally returned to the front-end treatment unit.

The steel structure integrated denitrification filter invented and designed by Yixing Boyu Environmental Protection Equipment Co., Ltd. is filled with air-water distribution filter bricks. It is especially suitable for use in small township sewage plants, river water treatment, etc. It has the advantages of short installation and commissioning time, low cost, convenient transportation, and stable treatment effect. The processing capacity of a single set of equipment is 300-400m3/d, and can be used in parallel to fully achieve the treatment effect of a civil construction tank.

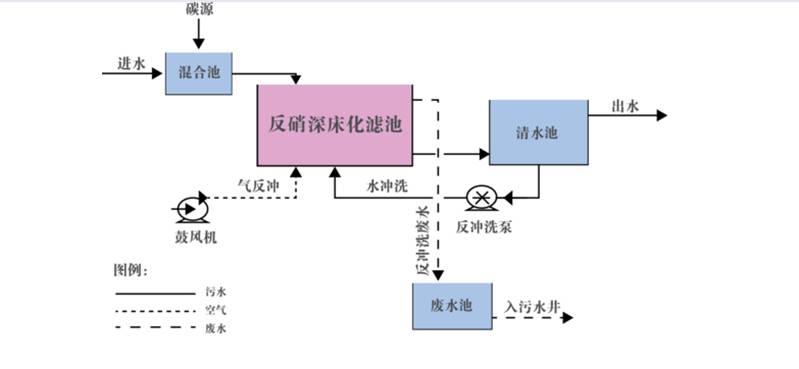

Process flow

Integrated filter internal structure

Components of the filter

ØPool structure: reinforced concrete or steel structure, usually rectangular.

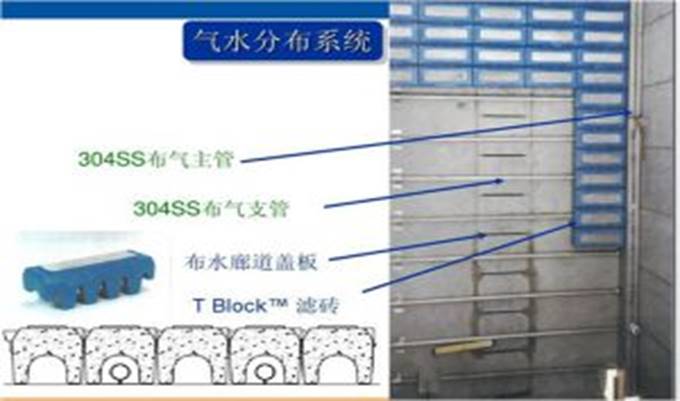

ØGas-water distribution system: adopts 'T' type gas-water distribution block filter brick technology to backwash stainless steel main and bronchial tubes; long-handled filter heads and filter plates are eliminated. No consumable parts.

ØFilter media: quartz sand filter material, filter bed height is about 1.8-2.5m, effective particle size is 2~4mm, uniformity coefficient: 1.4, sphericity is not less than 0.8, Mohs hardness: 6-7, specific gravity: greater than or equal to 2.6g/cm3, acid solubility: not more than 3%.

ØFilter material supporting layer: total thickness is about 450mm, with four grades of pebbles distributed.

ØBackwash pump: During backwash, the submersible centrifugal pump located in the clean water pool pumps the water to the bottom of the filter tank for powerful backwash.

ØBackwash blower: Roots blower is used to perform air scrubbing during backwash.

ØFilter automatic control valve: pneumatic or electric butterfly valve.

ØFilter weir plate: stainless steel weir plate.

ØFilter main control cabinet: PLC programmable controller, human-machine dialogue multi-interface display, which can provide the output of the central control system;

ØDosing system: Dosing of chemicals for chemical phosphorus removal and carbon source dosing during denitrification and denitrification are designed by the supplier.

ØFilter instrumentation: filter inlet flow meter, backwash flow meter, liquid level switch, etc., all designed by the design institute.

content is empty!