1. Overview

The fiber filter cloth turntable filter is one of the most advanced filters in the world. This technology has been adopted in many sewage plants in the world. The filter cloth turntable filter has good treatment effect, good effluent water quality, stable effluent water quality, reliable equipment operation and high degree of automation. It is an ideal reclaimed water reuse process filtration system equipment.

Fiber filter cloth turntable filters are mainly used for cooling circulating water treatment and wastewater reuse after advanced treatment. As cooling water and circulating water, filter and reuse: inlet water quality SS≤80mg/L or less, outlet water quality SS≤10mg/L. It is used for the advanced treatment of sewage. It is installed after the conventional activated sludge method, delayed aeration method, SBR system, oxidation ditch system, trickling filter system, and oxidation pond system. It can be used in the following fields: ①Remove total suspended solids ②Add chemicals to remove phosphorus ③Remove heavy metals, etc.

2. Design parameters of fiber turntable filter

Filtration type: filter cloth microfiltration

Filter disc diameter: DN2000mm (can be set separately)

Filter cloth mesh diameter: ≤10 microns

Filter cloth material: fiber filter cloth

Effective filter area: 5.2 m2 (single disk)

Water quality conditions before filtration: sewage secondary treatment effluent

Inlet water quality: SS≤30mg/l (instantaneous peak value 80mg/l)

Outlet water quality: SS≤5mg/l, turbidity≤2NTU Note: When inlet water SS≥50mg/l, the suspended solids filtration efficiency is 70%

Medium temperature: normal temperature

pH : 6~9

Operating cost: 0.01 yuan/ton of water (excluding depreciation costs

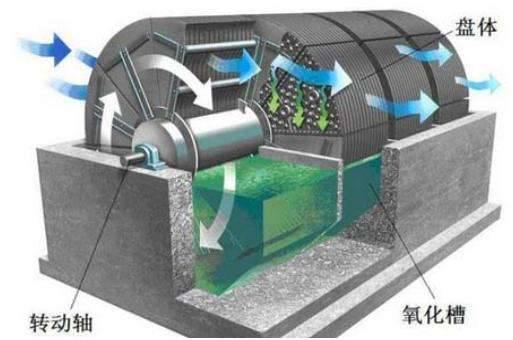

3. Structure of fiber turntable filter

The fiber turntable filter is mainly composed of (1) box body, (2) filter disc, (3) backwash mechanism, (4) mud discharge mechanism, (5) central tube, (6) driving mechanism, (7) electrical control, (8) pump and valve mechanism.

(1) Box body: carbon steel welded, with imported anti-corrosion paint on the inside and Baotashan epoxy zinc-rich anti-corrosion paint on the outside. The box body has a compact structure, light weight and small footprint. The auxiliary tank can adjust the water level drop.

(2) Filter disc: Each filter disc is composed of 6 independent pieces, covered with filter cloth and substrate. Depth of filter hair

Stores trapped particles to reduce head loss during normal operation. Each filter cloth filter disc has at least 5.2m2 (53.8 sq. ft.) of effective submersible filtration area and can be easily removed from the unit.

(3) Backwash mechanism: It consists of backwash suction port, pipeline, backwash suction port bracket components, etc. Used for backwashing filter cloth.

(4) Mud discharge mechanism: It consists of mud discharge suction port, pipe, mud discharge suction port bracket components, etc. Used to clean the sludge at the bottom of the filter.

(5) Central tube: After treatment, the reclaimed water flows into the auxiliary tank through the hollow tube. The hollow tube can both transport the reclaimed water and drive the filter disk to rotate.

(6) Driving mechanism: It consists of reducer, sprocket, chain, etc., and is used to drive the center tube and filter plate to rotate.

(7) Electrical system: It is composed of electric control box, PLC, touch screen, liquid level monitoring and other electronic control components. It is used to control the backwash and mud discharge process to automate its operation, and can adjust the backwash interval and mud discharge interval.

(8) Pump and valve mechanism: composed of centrifugal pump, pipeline and electric ball valve, used for backwashing and mud discharge.

4. Fiber turntable filter process operation mode

The operating status of the fiber turntable filter includes: static filtration process, negative pressure backwash process, and mud discharge process.

(1) Static filtration process: The gravity flow of sewage enters the filter, and the filter is equipped with baffle energy dissipation facilities. The sewage is filtered through the filter cloth, the filtrate is collected through the hollow tube, and the gravity flow is discharged from the filter tank through the overflow tank. The entire process is continuous.

(2) The negative pressure reverse position gradually increases. Detect the water level in the pool through a pressure monitoring device. When the water level reaches the backwash set value (high water level), the PLC can start the backsuction pump and start the backwash process. During backwashing, the filter tank can continuously filter.

During filtration, the filter disc is in a static state, which is conducive to the sedimentation of sludge at the bottom of the tank. During backwashing, the filter disc rotates at a speed of 1 rpm. The suction pump uses negative pressure to suck the surface of the filter cloth to remove the sludge particles accumulated on the filter cloth. The water in the filter plate is sucked at the same time. The water cleans the filter cloth from the inside out and discharges the backwashed water. The extraction and cleaning area only accounts for 1% of the total filter plate area. The backwash process is intermittent.

(3) Sludge discharge process: There is a bucket-shaped bottom under the filter plate of the fiber turntable filter, which is conducive to the collection of sludge at the bottom of the tank. The sedimentation at the bottom of the sludge pool reduces the amount of sludge on the filter cloth, which can extend the filtration time and reduce the amount of backwash water. After a set period of time, the PLC starts the sludge discharge pump and returns the sludge to the sewage pretreatment structure through the sludge discharge pipeline at the bottom of the pool.

5. Fiber turntable filter electronic control system

1. The electronic control system uses modern programmable controller PLC as the core of the program control system. Automatically control the backwashing of the filter cloth and the discharge of sludge. The electronic control core components of the system are S7200 series programming controllers and touch screens produced by Germany's Siemens. The main components are Schneider's top-quality products. They have reliable quality, excellent performance, strong adaptability to the environment, and good anti-interference performance. It is an ideal control system for reclaimed water treatment equipment.

2. The system has two modes: manual and automatic: In the automatic mode, the operator adjusts the backwash interval as needed, and the equipment can work according to the preset program of the PLC (controlled by time and liquid level); the manual mode is only used during equipment debugging or maintenance to realize manual control of valves, pumps, and filter plate motors, and can operate the corresponding key to complete the backwash function before shutdown or the pool cleaning function or the shutdown antifreeze function.

3. S7200 can be equipped with an Ethernet interface or DP interface communication interface module according to user requirements, which can realize data transmission with the factory main station.

4. Manual and automatic mode selection, parameter setting, status indication, and button operations are all completed on the touch screen; select from the initial interface to enter the corresponding interface, and click the corresponding button to complete the corresponding operation function.

5. The touch screen system has a fault alarm prompt function; it detects the opening and closing of valves, and detects overcurrent and overload of pumps and filter plate motors. When there is a fault, the touch screen displays fault information and generates audible and visual alarms.